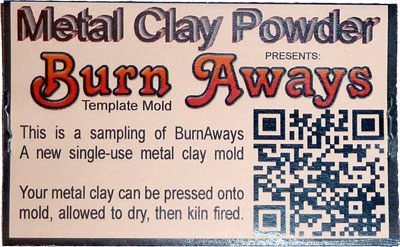

Bring your metal clay work into the digital age with Burn Aways

metal clay template molds

Burn Aways are made of pressed paper with an image engraved into its surface. Any metal clay can simply be pressed into the mold and allowed to dry before being fired in the kiln.

Burn Aways are versatile too! Depending on how your clay is prepared you can demold the Burn Aways and sometimes may be able to use them multiple times.

Economical and Ecological: Not made from costly rubber or silicone compounds, but made from part post-consumer paper products. So the savings are passed on for you to have your own custom made Burn Aways for less than other standard molds.

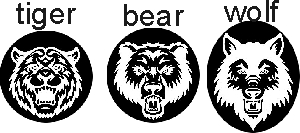

Image with Depth: Burn Aways gives you 3D printed like designs with the depth you need for oxidated contrasts and colored enameling. The relief (engraved depth) of the mold is typically .7mm - .9mm in depth. meaning your unfired clay could have a raised design that is up to 9/10'ths of a millimeter from base.

Use Burn Aways molds for medallions, coins, charms, buttons and rings.

Using Burn Aways Molds

Metal clay that is pressed into the mold generally does not stick to it as it dries, but however if it was pressed onto with great force such as with a rolling pin, or the clay was very moist the clay may stick to it as it dry. Very detailed molds may also stick and its image can tear away from the mold when dried.

It is important that you allow the metal clay to fully dry before attempting removing the mold. Still moist or soft clay can become stuck in the design of the mold thus ruining your clay creation.

The Burn Aways molds have there images burned away off the paper. That image actually has a microscopic layer of ash which further makes the clay less likely to adhere to the mold as it dries.

And as its name implies, the mold can be burned away in a kiln. If you feels your metal clay is too fragile to pull away from the mold, you can place the whole piece mold side down in the kiln and fire it as you would any other metal clay. The average Burn Aways mold will vaporize to just a few thousandths of a gram of ash.

Remember the dark or engraved area of the mold will be the raised areas of your finished clay. See the 'tiger' mold and silver right.